Materials for Construction Scale 3D Printing

Embark on a journey of innovation and sustainability with our construction-scale 3D printing materials. Explore the possibilities of cutting-edge materials in construction-scale 3D printing, where innovation meets sustainability to shape the future of the built environment.

Revolutionizing the Construction Industry

AUTOCON delves into the advanced and diverse range of polymers and cementitious materials utilized in construction-scale 3D printing. Our innovative approach combines cutting-edge technology with sustainable materials to revolutionize the construction industry. AUTOCON’s universal material toolkit unveils the diverse palette of materials powering the capabilities of construction-scale 3D printing. Our commitment to innovation is reflected in the meticulous selection of polymers, thermoplastics, cementitious composites, metal composites, and indigenous composites, each tailored to meet the unique demands of advanced construction methodologies. As we develop novel polymers, composites, and indigenous printable materials, we provide a foundation for technological advancements as they mature, especially for fabrication of 3D-printed structures and/or structural components in expeditionary environments using indigenous materials for low resource manufacturing.

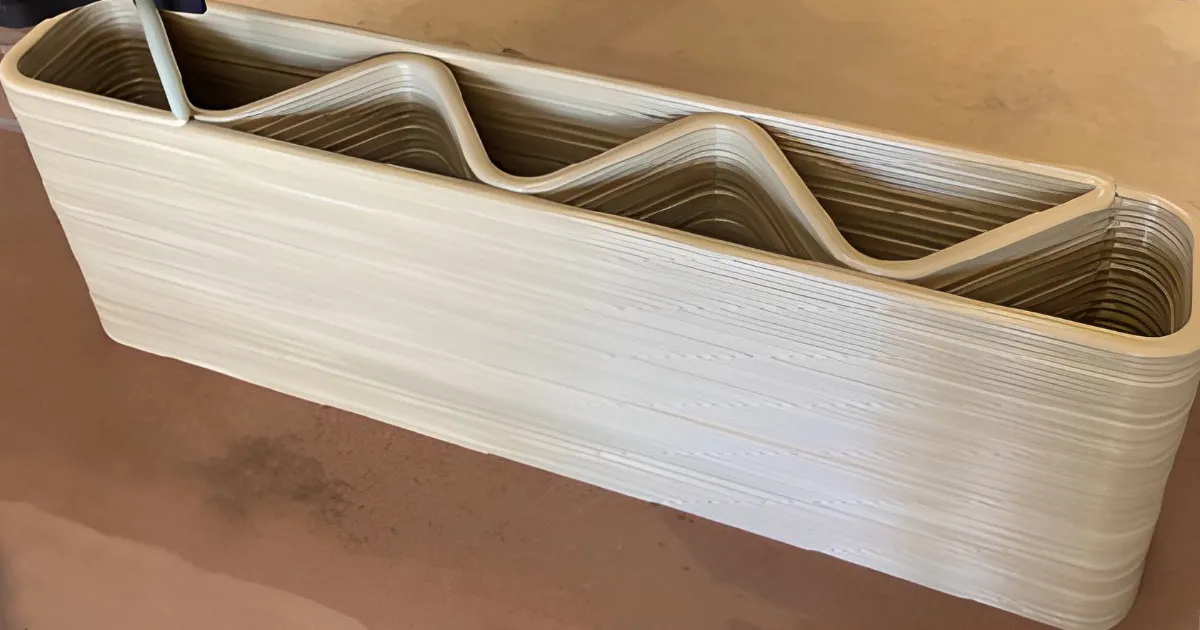

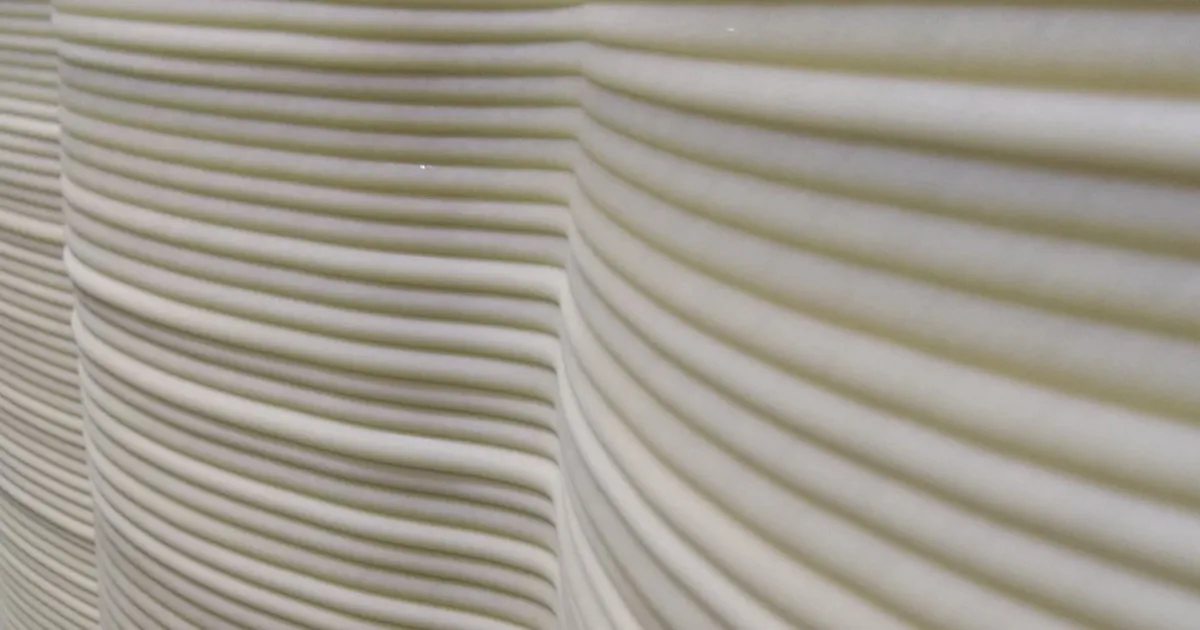

Polymers for Structural Flexibility

Our construction-scale 3D printing leverages high-performance polymers renowned for their exceptional structural flexibility, durability, and design adaptability. We only employ high-performance polymers designed for structural integrity, adaptability, and versatility including environmentally friendly. These materials go through a rigorous R&D process before being selected to meet the demanding requirements of construction-scale 3D printing projects. Some of the main benefits are:

- High Tensile Strength: Ensures structural stability and resilience in construction applications.

- Customizable Formulations: Tailored to meet project-specific requirements.

- Weather Resistance: Withstands environmental elements for long-lasting structures.

- Innovative Design: Facilitates intricate and dynamic architectural designs.

- Flexibility: Allows for design complexity and adaptability.

Thermoplastics for Rapid Construction

We incorporate thermoplastics to facilitate rapid 3D printing that is minimally affected by outside environmental factors, enabling a swift and adaptable construction process.

- Quick Set Times: Accelerates construction timelines without compromising quality due to environmental factors.

- Design Freedom: Allows for on-site adjustments and modifications.

- Energy Efficiency: Supports energy-efficient construction practices.

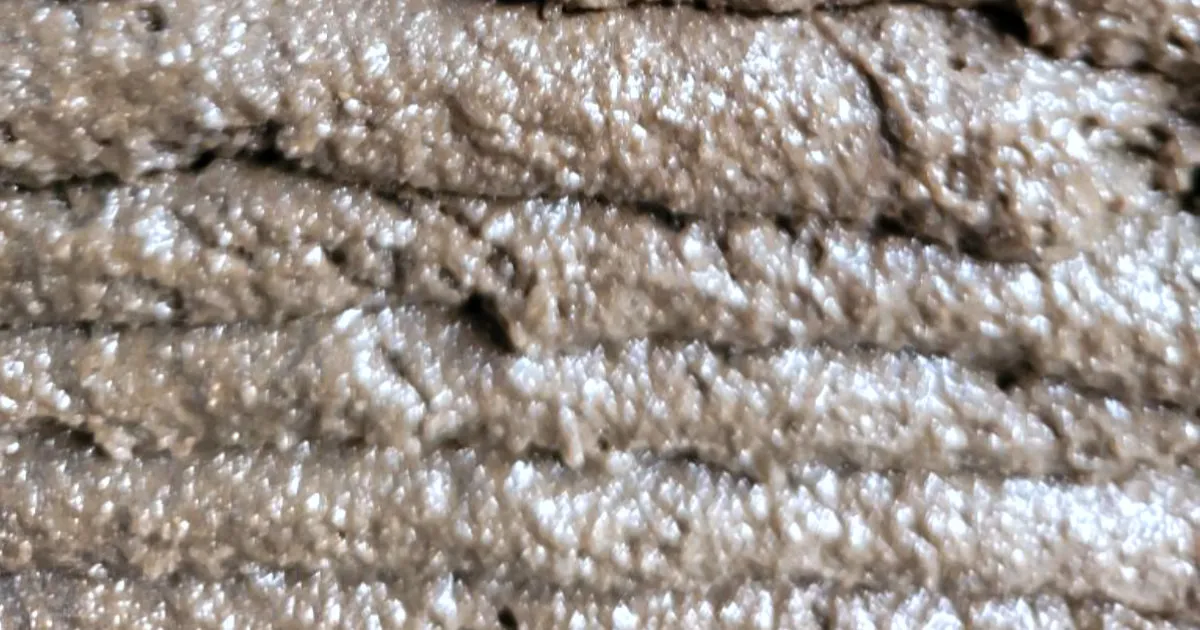

Cementitious Composites for Structural Stability

Our cementitious composites merge traditional construction materials with cutting-edge additives, providing a robust foundation for stable and enduring 3D-printed structures. These blends are proprietary and specifically designed for our universal material toolkit. These cementitious composites consist of:

- Excellent Adhesion: Ensures cohesion between layers for structural soundness.

- Rapid Set Times: Accelerates construction processes without compromising quality.

- Environmental Sustainability: Integrates eco-friendly additives for reduced environmental impact.

- Adaptability: Compatible with various construction methods and designs.

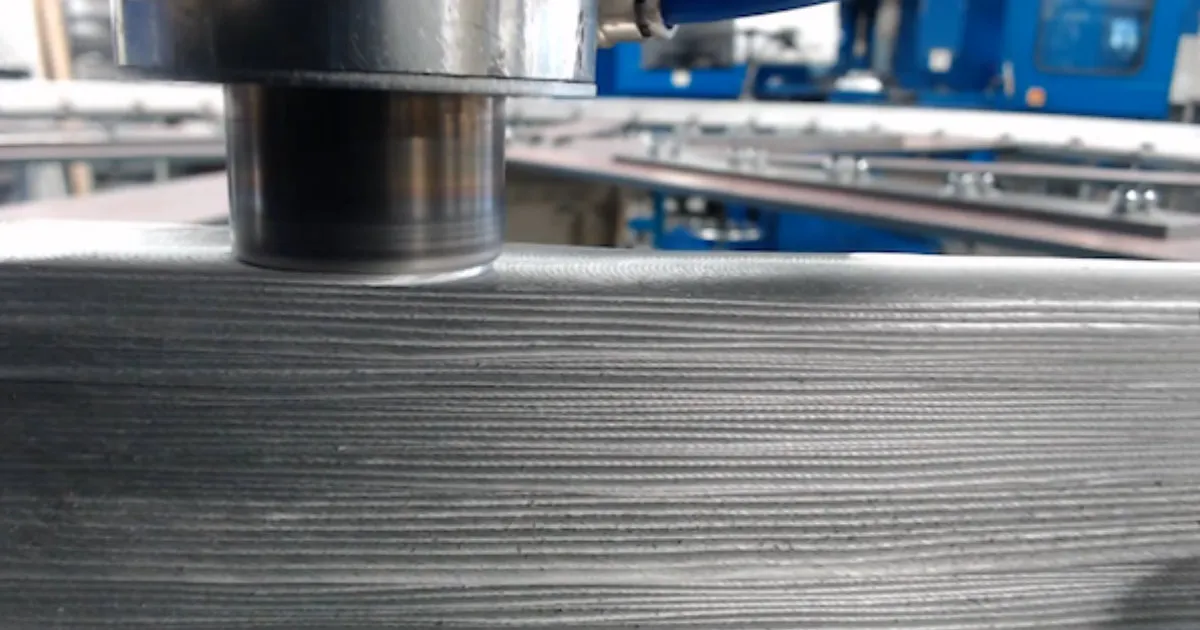

Metal Composites for Enhanced Strength

Incorporating metal composites strengthens our commitment to constructing resilient and load-bearing structures, with a focus on advanced strength and durability. The major advantages of our metal composites are:

- High Load-Bearing Capacity: Ideal for structural elements demanding increased strength.

- Corrosion Resistance: Guards against degradation over time.

- Thermal Conductivity: Suitable for applications requiring controlled temperature environments.

Indigenous Composites for Sustainable Construction

Embracing sustainable practices, our use of indigenous composites emphasizes local materials and traditional knowledge, fostering environmentally conscious construction solutions. Our research-driven approach incorporates composite materials, combining the benefits of polymers and cementitious blends. These hybrid materials amplify the strengths of each component, resulting in superior construction-grade substances. As a result, the materials have excellent:

- Strength-to-Weight Ratio: Enhances load-bearing capabilities without excess weight.

- Crack Resistance: Minimizes the risk of structural defects over time.

- Thermal Insulation: Improves energy efficiency and occupant comfort.

- Chemical Resistance: Guards against corrosion and degradation.

- Cultural Integration: Incorporates locally-sourced materials to reflect regional identity.

- Low Environmental Impact: Utilizes materials that align with sustainable and ethical sourcing.

- Community Collaboration: Engages local communities in construction processes.

Developing New Technologies to 3D Print Buildings & Structures On-Site

Through the integration of robotics, software, and materials science, we are addressing the challenges of today's construction landscape, making it more efficient, cost-effective, and sustainable.

© AUTOCON Technologies Inc. All Rights Reserved.

Houston TX - Austin TX - Huntsville AL